Featured Application | Sumitomo (SHI) Demag Plastics Machinery GmbH

Application report: Top performance in continuous operation

- INDUSTRY: MECHANICAL ENGINEERING - Injection moulding machines

- TYPICAL APPLICATIONS: DC 24 V PROTECTION

- PRODUCT SOLUTION: (REX SYSTEM) REX12D-T / IO link

Sumitomo (SHI) Demag stands for tradition and innovation of excellent injection moulding technology from Germany and Japan, combining strengths from the two countries that have made mechanical engineering the most successful in the world.

The product portfolio includes fully electrical and hybrid-driven injection moulding machines with clamping forces of 180 up to 15,000 kN. With more than 145,000 installed machines, Sumitomo (SHI) Demag is represented in all important markets worldwide and with more than 3,000 employees, it is one of the leading global manufacturers of injection moulding machines.

“With the compactness, easy mounting and modularity of the REX-12 system, E-T-A proofs their ability to create innovative and reliable products from customer requirements.”

Jan Taufer, Master of Engineering (TH), Condition Monitoring project manager, Sumitomo (SHI) Demag Plastics Machinery GmbH

Technology driver for development in the field of partially and fully electric injection moulding machines

Whether in the packaging industry, medical technology, the automotive industry, the consumables industry or the electronics sector, Japanese precision and discipline combined with German engineering skills guarantee top performance in continuous operation.

Our passion for innovation enables us every day to support our customers with system solutions and services that are perfectly tailored to their applications.

Customised innovation with the REX-12 system

The REX-12 system already convinces during installation, thanks to its fast and easy DIN rail mounting. Its minimised installation space requirement and the easy connection to the circuit protectors contribute to the small footprint of the machine.

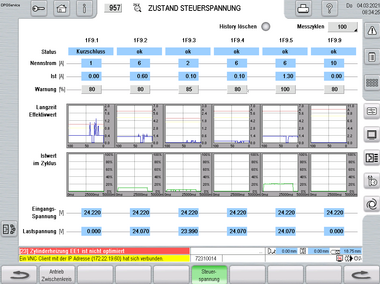

The large number of available fuses and their compatibility with each other allows implementation of safe monitoring of the 24 V circuits as a standard. There is the option to communicate with the system control via IO link by simply changing the supply module and to monitor status data, as well as actual current and voltage values.

This way of Condition Monitoring helps detecting potentially critical conditions at an early stage and simplifies troubleshooting in the event of a failure.

All benefits at a glance

- Increased machine uptime

- Condition Monitoring based on IO link

- Compactness, easy mounting, modularity and simple handling